Shredding

Perforators and flatteners for PET beverage bottles

The following machines are available:

- Mobile PET perforation systems as add-on units, capacity up to 800 kg/h

- PET perforators with punching mandrels, capacity up to 4,000 kg/h

- Low-wear PET flattening system without a cutting knife, punching mandrels or nails, capacity up to 4,500 kg/h

Bag opener/bale breaker

The following versions are available:

- Bag opener with a drum fitted with ripper teeth. Opens bags or singles bales without crushing the contents

- Slow-running bale crushers or pre-shredders with 2 to 8 crusher shafts

- The systems are suitable for waste wood, gypsum board waste, mixed building waste, insulation materials, paper, chipboard, car bumpers, electronic waste, refuse bins, paper and pulp bales, PET bales, straw bales etc.

Cutting mills and grinders

The following versions are available:

- Cutting, hammering or impact grinding mills for machining plastics into flakes or powders

- Drum chippers for machining tree trunks, wood flitches or sawmill waste for burning chips or high quality chippings for the pellet or cellulose industry

- Mobile shredders for shredding green cuttings or tree trunks

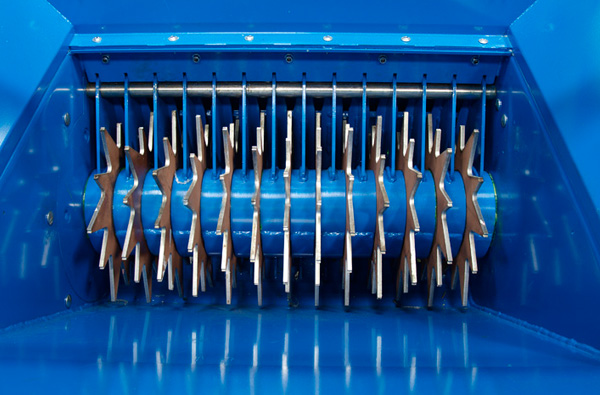

Single and twin shaft shredders

The following shredders with a capacity of up to 50 t/h are available:

- Single shaft shredder for pre- and post-crushing of valuable waste materials or for destroying files and data carriers

- Twin shaft shredder with TAIFUN cutting unit or TORNADO shredding shaft as pre-crusher

- Twin shaft shredder with HURRICANE cutting unit as pre- or post-crusher

Reel splitter machines

The following reel splitter machines are available:

- Mechanical reel splitter for coring small reels

- Hydraulic reel splitting machines with mandrel fixture for cutting residual rolls with Ø 1,200 mm and length 1,500 mm

- Hydraulic cutting table reel splitting machines for the cutting of reel material with Ø 2,500 mm and a length of 3,600 mm

- With accessories such as reel dumper as well as feed and discharge systems