Machines

Own products

Complex tasks require innovative solutions. It is often the case that we have the optimal solution for a processing operation, but the machine, which is to meet the requirements, is not yet available. Then we simply build it ourselves.

Our engineering department has developed many innovative solutions which are ecologically and economically sustainable. For example, PET perforators and PET flatteners, disc filters, label sorters and many more.

Machine construction for customers

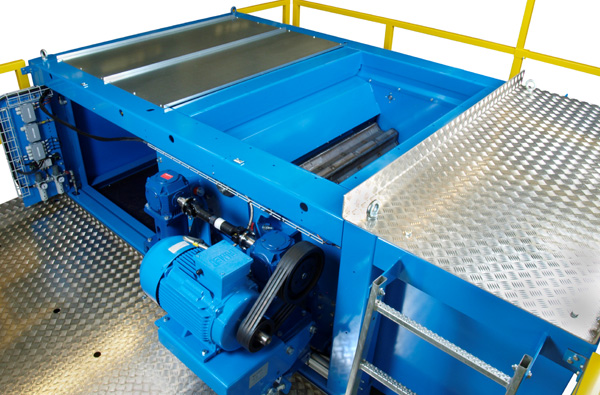

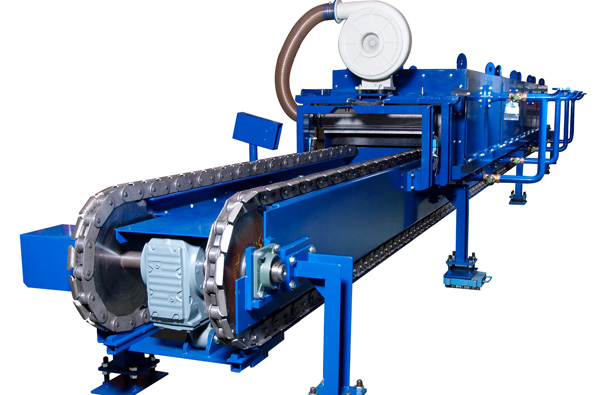

In addition to our own products, we also build a wide range of equipment and machines for our customers as part of order processing.

A redesign is often associated with this. We optimise the drawings so that the products can be manufactured and assembled more cost-effectively. The machines are assembled in our production and assembly halls and are made ready for operation.

Production and assembly hall

In our production and assembly hall we have a modern machine park, which allows the construction of machines weighing up to 30 tonnes.

The hall height of 14 meters also allows the construction of entire system components, which can be tested 1:1 under practical condition.

Special plants

If you are looking for a competent partner for the construction of new innovative machines, we are the right contact for you. We take this on with every job. Example: due to a customer request we have built a compacting plant for used oil filters. The output:

- Waste oil as a substitute fuel for the cement industry

- High quality steel scrap for the steel industry

- Return of investment is about 2 years

Using know-how to find a solution

We are innovative, possess know-how, have qualified and highly trained employees and are willing to learn new things.

We love challenges and have kept our discoverer spirit. If there is (still) no solution for a task, we will find one. You think it’s impossible? Borema makes it possible! So you can say “right solution – right decision”.